Working to advanced rotor technologies for U.S. offshore wind power generation, Sandia scientists are searching for the most-workable design for a vertical axis wind turbine blade by creating several concept designs and running those designs through modern modeling software.

Sandia National Laboratories’ wind energy researchers are re-evaluating vertical axis wind turbines (VAWTs) to help solve some of the problems of generating energy from offshore breezes.

Though VAWTs have been around since the earliest days of wind energy research at Sandia and elsewhere, VAWT architecture could transform offshore wind technology.

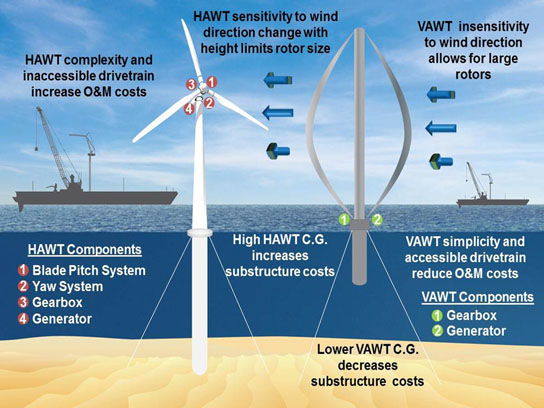

The economics of offshore wind power are different from land-based turbines, due to installation and operational challenges. VAWTs offer three big advantages that could reduce the cost of wind energy: a lower turbine center of gravity; reduced machine complexity; and better scalability to very large sizes.

A lower center of gravity means improved stability afloat and lower gravitational fatigue loads.

Additionally, the drivetrain on a VAWT is at or near the surface, potentially making maintenance easier and less time-consuming. Fewer parts, lower fatigue loads and simpler maintenance all lead to reduced maintenance costs.

Elegant in their simplicity

Sandia is conducting the research under a 2011 Department of Energy (DOE) solicitation for advanced rotor technologies for U.S. offshore windpower generation. The five-year, $4.1 million project began in January of this year.

Wind Energy Technologies manager Dave Minster said Sandia’s wind energy program is aimed at addressing the national energy challenge of increasing the use of low-carbon power generation.

“VAWTs are elegant in terms of their mechanical simplicity,” said Josh Paquette, one of Sandia’s two principal investigators on the project. “They have fewer parts because they don’t need a control system to point them toward the blowing wind to generate power.”

These characteristics fit the design constraints for offshore wind: the high cost of support structures; the need for simple, reliable designs; and economic scales that demand larger machines than current land-based designs.

Large offshore VAWT blades in excess of 300 meters will cost more to produce than blades for onshore wind turbines. But as the machines and their foundations get bigger — closer to the 10–20 megawatt (MW) scale — turbines and rotors become a much smaller percentage of the overall system cost for offshore turbines, so other benefits of the VAWT architecture could more than offset the increased rotor cost.

Challenges remain

However, challenges remain before VAWTs can be used for large-scale offshore power generation.

Curved VAWT blades are complex, making manufacturing difficult. Producing very long VAWT blades demands innovative engineering solutions. Matt Barone, the project’s other principal investigator, said partners Iowa State University and TPI Composites will explore new techniques to enable the manufacture of geometrically complex VAWT blade shapes at an unprecedented scale, but at an acceptable cost.

VAWT blades must also overcome problems with cyclic loading on the drivetrain. Unlike horizontal axis wind turbines (HAWTs), which maintain a steady torque if the wind remains steady, VAWTs have two “pulses” of torque and power for each blade, based on whether the blade is in the upwind or downwind position. This “torque ripple” results in unsteady loading, which can lead to drivetrain fatigue. The project will evaluate new rotor designs that smooth out the amplitude of these torque oscillations without significantly increasing rotor cost.

Because first-generation VAWT development ended decades ago, updated designs must incorporate decades of research and development already built into current HAWT designs. Reinvigorating VAWT research means figuring out the models that will help speed up turbine design work.

“Underpinning this research effort will be a tool development effort that will synthesize and enhance existing aerodynamic and structural dynamic codes to create a publicly available aeroelastic design tool for VAWTs,” Barone said.

Needed: aerodynamic braking

Another challenge is brakes. Older VAWT designs didn’t have an aerodynamic braking system, and relied solely on a mechanical braking system that is more difficult to maintain and less reliable than the aerodynamic brakes used on HAWTs.

HAWTS use pitchable blades, which stop the turbine within one or two rotations without damage to the turbine and are based on multiple redundant, fail-safe designs. Barone said new VAWT designs will need robust aerodynamic brakes that are reliable and cost-effective, with a secondary mechanical brake much like on modern-day HAWTs. Unlike HAWT brakes, new VAWT brakes won’t have actively pitching blades, which have their own reliability and maintenance issues.

VAWT technology: A long history at Sandia

In the 1970s and 1980s, when wind energy research was in its infancy, VAWTs were actively developed as windpower generators. Although strange looking, they had a lot going for them: They were simpler than their horizontal-axis cousins so they tended to be more reliable. For a while, VAWTs held their own against HAWTs. But then wind turbines scaled up.

“HAWTs emerged as the predominant technology for land-based wind over the past 15 years primarily due to advantages in rotor costs at the 1 to 5 megawatt scale,” Paquette said.

In the 1980s, research focused more heavily on HAWT turbines, and many VAWT manufacturers left the business, consigning VAWTs to an “also ran” in the wind energy museum.

But the winds of change have blown VAWTs’ way once more.

Sandia is mining the richness of its wind energy history. Wind researchers who were among the original wind energy engineers are going through decades of Sandia research and compiling the lessons learned, as well as identifying some of the key unknowns described at the end of VAWT research at Sandia in the 1990s.

The first phase of the program will take place over two years and will involve creating several concept designs, running those designs through modern modeling software and narrowing those design options down to a single, most-workable design. During this phase, Paquette, Barone and their colleagues will look at all types of aeroelastic rotor designs, including HVAWTs and V-shaped VAWTs. But the early favorite rotor type is the Darrieus design.

In phase two researchers will build the chosen design over three years, eventually testing it against the extreme conditions that a turbine must endure in an offshore environment.

In addition to rotor designs, the project will consider different foundation designs: Early candidates are barge designs, tension-leg platforms and spar buoys.

The project partners will work on many elements.

Another partner, the University of Maine, will develop floating VAWT platform dynamics code and subscale prototype wind/wave basin testing. Iowa State University will develop manufacturing techniques for offshore VAWT blades and subscale wind tunnel testing. TPI Composites will design a proof-of-concept subscale blade and develop a commercialization plan. TU-Delft will work on aeroelastic design and optimization tool development and modeling. Texas A&M University will work on aeroelastic design tool development.

“Ultimately it’s all about the cost of energy. All these decisions need to lead to a design that’s efficient and economically viable,” said Paquette.

1 Comment

On the torque ripple / power pulse problem, might a third or fourth blade help? Or would this

chop & mess up the air flow?

Could helical blades solve this?

The V-shape idea is interesting.

When one VAWT is downwind of another,

Having one of the V’s point up and the other down

might amount to “sharing” the wind’s flow. (This might only be more advantageous in light wind.)

In an area with high prevailing winds, a

diamond-shaped VAWT between the opposed V’s might be useful, but only if the three of them could pivot into the wind as a group, and if the benefit would justify the extra construction.

Good luck!

Marty